Discover the Major Industrial Regions of India with Key Facts for upcoming competitive exams. Industrial regions, the powerhouses of a nation’s economy, are not just geographical locations but vibrant ecosystems where businesses thrive, fueled by proximity, shared resources, and a skilled workforce. These regions are often born out of necessity, clustering around natural resources like coal, iron ore, water sources, or transportation hubs like ports and railways.

✅ Explore the Complete List of Indian Geography Topics

What are Industrial Regions?

- Industrial regions are locations where industries have concentrated due to favourable geo-economic conditions.

- These areas witness a significant portion of the population employed in large-scale manufacturing operations.

- Unlike smaller industrial parks, an industrial region can be expansive, resembling examples such as the Ruhr in Germany or the Midlands in the UK, which may constitute a substantial part of a nation.

- Typically centred around a key natural resource like coal, iron ore, or a water source, these regions are strategically positioned with well-developed transportation routes such as railways.

- They often exhibit diversity in manufacturing, encompassing unrelated industries like education, primary food processing, steel manufacturing, and power generation within a single location.

- Residential areas may be nearby or interspersed within industrial regions, driven by the higher labour demands of these complex operations.

- Various geographers have attempted to define industrial regions experimentally, yet the criteria they employ tend to vary.

- Typically, industrial regions are designated for industrial operations, often leading to lower property values compared to residential or commercial areas.

- Governments and planning agencies often prefer grouping manufacturing facilities together for various reasons, including controlling pollution, minimizing noise, managing heavy traffic, and addressing safety concerns associated with industrial activities.

- Additionally, clustering industrial establishments promotes collaboration and efficiency, such as the proximity of transportation services to manufacturing plants.

- However, industrial regions may face challenges, including lower property values, increased crime rates in adjacent commercial and residential zones, and potential risks associated with industrial activities.

- The development of a city or country typically starts with more industrial zones, with a shift towards more commercial zones as the area matures.

- While many regions evolve from industrial to commercial dominance, some areas may remain heavily industrialized throughout their histories.

The early history of Industrial Regions

- The concept of industrial regions was first introduced by American geographers Trewartha and Burner in 1944.

- They identified and classified India’s industrial regions based on factors such as resource availability, transportation infrastructure, and industrial concentration.

- Subsequently, other scholars like P.P. Karan, W.M. Jenkrins, Spencer, Thomas, R.L. Singh, B.N. Sinha, M.R. Chaudhry, and the Centre for Monitoring Indian Economy (CMIE) made significant contributions to refining the definition and identification of India’s industrial regions.

- The term “industrial district” was first coined by Alfred Marshall, a British economist, in 1890.

- He used the term to describe a geographical area where businesses in a particular industry are concentrated and interconnected.

- Marshall observed that industrial districts often exhibit a high degree of specialization, cooperation, and innovation.

- By the late 20th century, industrial districts had emerged as a focal point of discussions on industrialization and regional development strategies.

- Their ability to foster innovation, entrepreneurship, and economic growth attracted the attention of policymakers and scholars worldwide.

Timeline of Industrial Region Studies in India in a nutshell

| Year | Researchers | Contribution |

|---|---|---|

| 1944 | Trewartha and Burner | Identification of India’s industrial regions |

| 1959 | P.P. Karan and W.M. Jenkins | Definition of India’s industrial areas |

| 1968 | Spencer and Thomas | Refinement of the definition of India’s industrial regions |

| 1971 | R.L. Singh | Detailed classification of India’s industrial regions |

| 1972 | B.N. Sinha | Comprehensive analysis of India’s industrial regions |

| 1976 | M.R. Chaudhry | Comparative study of India’s industrial regions |

| 1971, 1982 | Centre for Monitoring Indian Economy (CMIE) | Publication of reports on India’s industrial regions |

Indices and Types of Industrial Regions in India

Indices play a crucial role in identifying the clustering of industries, leading to the formation of industrial regions that capitalize on favourable locational factors. These regions often concentrate on specific areas due to advantageous variables.

Several key indices are employed to ascertain the clustering of industries:

- The count of industrial units.

- The number of industrial workers.

- The population engaged in secondary activities.

- Percentage of industrial workers among total workers.

- Quantum of power utilized for industrial purposes.

- Total industrial output (Gross industrial output).

- Value added by manufacturing and more.

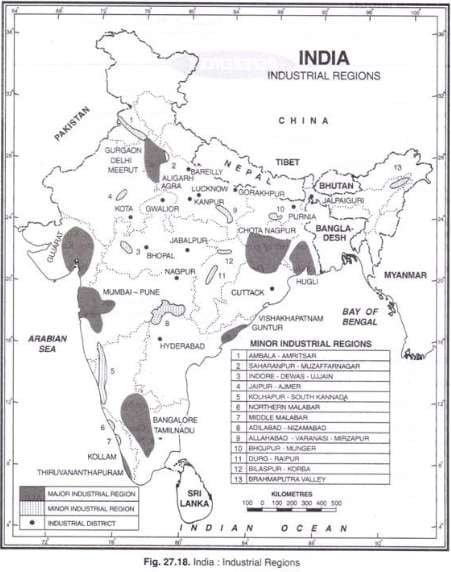

In India, notable industrial regions include the Kollam Thiruvananthapuram industrial cluster, the Mumbai-Pune cluster, the Bangalore-Tamil Nadu region, the Hugli region, the Ahmedabad-Baroda region, the Chottanagpur industrial belt, the Vishakhapatnam-Guntur belt, the Gurgaon-Delhi-Meerut region, among others.

These industrial regions can be categorized into two types:

- Major Industrial Regions

- Minor Industrial Regions

8 Major Industrial Regions of India: A Brief Overview by Prof. R.L. Singh

India’s industrial regions have been categorized into eight main divisions by experts, following the boundaries outlined by Prof. R.L. Singh. As per Prof. R.L. Singh’s classification, these industrial areas are briefly outlined below.

The Mumbai-Pune Industrial Region

History and Location

- The Mumbai-Pune Industrial Region is the foremost manufacturing hub in India.

- Its development was catalyzed by the establishment of the Mumbai seaport during the British colonial period.

- The introduction of the Suez Canal in 1869 further boosted its growth.

Factors Contributing to its Growth

- Historical advancements in the cotton textile industry.

- Favorable humid climate.

- Natural port facilities.

- Access to hydropower.

- Skilled workforce.

- Vast hinterland producing cotton.

Key Statistics

- Over 8000 registered factories in the Mumbai area alone, with 350 dedicated to cotton textiles.

- Employs over 15 lakh people in the industrial sector.

- Pune, the second-largest hub, has over 1200 factories specializing in diverse products.

- Other prominent manufacturing hubs include Ambarnath, Andheri, Thane, etc.

Challenges Faced

- Saturation due to rapid development.

- Inadequate power supply.

- Outdated machinery.

- High land and commercial space costs.

- Labor unrest.

- Increasing regionalism and crime rates.

- Growing environmental pollution.

Impact of Partition and Future Prospects

- The 1947 partition negatively impacted the region, with the loss of long-staple cotton production.

- Mumbai faces limitations due to space constraints.

- Dispersing businesses is crucial to alleviate congestion and ensure future growth.

The Kolkata-Hugli Industrial Region: Key Details

Location and Geography

- Situated along the Hooghly River, flowing through the Rarh region of West Bengal.

- Strategically located with an inland river port at its heart.

- Close proximity to coal mines (Raniganj and Jharia) and agricultural resources.

Factors Driving Industrial Growth

- Access to essential resources: coal, raw materials (jute, indigo, tea), water, and affordable labour.

- Export facilities via the Kolkata port.

- Historical significance: Kolkata served as the capital of British India (1773-1911), attracting many industries.

Industrial Profile

- Over 10,000 registered factories employing 20 lakh people.

- Diverse production: jute, silk, cotton textiles, engineering goods, electrical goods, automobiles, chemicals, pharmaceuticals, transport equipment, leather footwear, iron and steel, food processing, light machinery, locomotives, and spare parts.

- Major industrial cities: Naihati, Bhatpara, Shamnagar, Krishnanagar, Serampore, Titagarh, Rishra, Kolkata, Haora, and Budge Budge.

Challenges and Initiatives

- Limited space and traffic congestion.

- Water scarcity, unsanitary conditions, and inadequate infrastructure.

- Silting of the Hugli River impacting Kolkata port.

- Outdated machinery and infrastructure.

- Political and labour unrest.

- Power supply shortages.

- West Bengal government’s liberalization policy to attract investments.

- Recent progress in addressing some challenges.

The Ahmadabad-Vadodara Industrial Region: Key Details

Industrial Significance

- Rank: Third-largest industrial area in India.

- Growth Drivers: Proximity to diverse energy sources (petroleum, thermal, hydel, nuclear). Availability of inexpensive land, skilled labour, and port facilities.

Industry Focus

- Cotton Textiles: Second-largest centre in India.

- Engineering Products, Pharmaceuticals, Chemicals.

- Vadodara: Petroleum and woolen textiles.

- Surat: Diamond cutting and silk textiles.

- Other hubs: Anand, Ankleshwar, Bhavnagar, Bharuch, Godhra, Jamnagar, Kalol, Kheda, Rajkot, Surendernagar.

Challenges

- Shortage of quality cotton and water.

- Impact of recent racial tensions on business investments.

The Madurai-Coimbatore-Bangalore Industrial Region: Key Details

Location and Significance

- Spans across Tamil Nadu and Karnataka, experiencing significant growth post-independence.

- A major contributor to the nation’s cotton production.

Factors Driving Growth

- Favorable climate: Supports agricultural and industrial needs.

- Skilled and unskilled labour force: Disciplined and readily available.

- Consistent power supply: Mettur, Papanasam, Pykara, Savitri, and Sivasamudram power plants ensure reliable energy.

- Proximity to seaports: Chennai, Kochi, Mangalore, and Tuticorin facilitate international trade.

Industrial Profile

- Primary Industry: Textiles (60% of workforce).

- Other Industries:

- Engineering (18%): Automobile manufacturing and related industries.

- Food Processing (12%): Leveraging agricultural produce.

- Other key sectors are IT (Bangalore), pharmaceuticals, leather goods, and tourism.

Economic Impact

- A major contributor to the regional and national economy.

- Provides employment opportunities to millions.

- Plays a vital role in India’s exports.

The Chotanagpur Industrial Region: The Ruhr of India

Location and Significance

- Comprises Jharkhand, Odisha, Southern Bihar, and western West Bengal.

- Nicknamed the “Ruhr of India” due to its importance in iron and steel production.

- Abundant mineral resources and cheap labour contribute to its industrial strength.

Mineral Resources and Power Supply

- Rich in solid minerals (coal, iron ore, manganese, mica) and non-metallic minerals (limestone, bauxite, dolomite).

- Fossil fuel reserves include coal and lignite.

- The Damodar Valley Company supplies power.

- A large workforce is available from Bihar, Jharkhand, Odisha, Uttar Pradesh, and West Bengal.

Major Industrial Centers

- Iron and Steel Production: Asansol, Bokaro, Burnpur, Durgapur, Kulti, Jamshedpur, Raurkela.

- Glass Industry: Ramgarh, Bhurkunda.

- HMT: Ranchi.

- Locomotives: Chittranjan.

- Fertilizer: Sindri.

Challenges and Opportunities

- Power Supply: Lack of reliable power supply can hinder industrial operations.

- Political Unrest: Naxalite activities and labour disputes discourage some investors.

- Opportunities: Government initiatives to improve infrastructure and attract investment.

- Potential: The region can become a major industrial hub in India.

Additional Information

- The region also has several engineering, chemical, and pharmaceutical industries.

- The Chotanagpur Plateau is a biodiversity hotspot, with several national parks and wildlife sanctuaries.

- The region is facing challenges such as pollution and deforestation.

Agra-Delhi-Kalka-Saharanpur Industrial Region: Key Details

Location

- Located in northern India.

- Major cities: Agra, Delhi, Ambala, Chandigarh, Faridabad, Ghaziabad, Gurgaon, and Kalka.

Industries

- Textiles: Agra, Delhi, Chandigarh, Kalka

- Chemicals: Delhi, Ghaziabad

- Drugs and pharmaceuticals: Delhi

- Light machinery: Delhi

- Electronic goods: Delhi, Gurgaon

- Food processing: Delhi, Gurgaon, Kalka

- Engineering: Faridabad

- Synthetic fibres: Ghaziabad

- Agricultural equipment: Ghaziabad

- Iron and steel: Ghaziabad

- Paper: Kalka

- Woodwork: Kalka

- Sugar: Kalka

- Scientific instruments: Ambala

- Strategic goods: Chandigarh

- Automobiles: Gurgaon

- Tourism: Agra

Challenges

- High cost of land

- Traffic congestion

- High crime rate

Prominent Industrial Centers

- Agra

- Delhi

- Ambala

- Chandigarh

- Faridabad

- Ghaziabad

- Gurgaon

- Kalka

Vishakhapatnam-Guntur Region: Key Details

Location and Geography

- Stretches from Vishakhapatnam district to Kurnool and Prakasam districts.

- Relies on Vishakhapatnam and Machilipatnam ports.

- Surrounded by developed agriculture and rich mineral reserves.

- Energy source: Godavari basin coalfields.

Economic Base

- Shipbuilding (started in 1941)

- Petroleum refineries (using imported petroleum)

- Petrochemical industries

- Developed agriculture

- Rich mineral reserves

Key Sectors

- Agriculture-based: Sugar, textiles, jute, paper

- Manufacturing: Fertilizers, cement, aluminium

- Other: Light engineering

Prominent Industrial Centers

- Vishakhapatnam

- Vijayawada

- Vijaynagar

- Rajahmundry

- Guntur

- Eluru

- Kurnool

Kollam-Thiruvananthapuram Region: Key Details

Geography

- Spans across districts of Thiruvananthapuram, Kollam, Alwaye, Ernakulam, and Alappuzha.

- Located far from mineral-rich areas of India.

Economic Base

- Plantation agriculture and hydropower form the foundation.

- Focus on agricultural product processing and market-oriented light industries.

Key sectors

Agriculture:

- Coconut oil extraction

- Rice milling

- Fish packing

- Coir-matting

Manufacturing:

- Cotton textiles

- Sugar

- Rubber

- Matchbox

- Glass

- Chemical fertilizers

- Fish-based industries

- Food processing

- Paper

- Coconut coir products

- Aluminum

- Cement

Other:

- Shipbuilding (Kochi)

- Petroleum refining (Kochi)

- Chemical and electronic goods manufacturing

Significant hubs

- Kollam

- Thiruvananthapuram

- Alwaye

- Kochi

- Alappuzha

- Punalur

The Minor Industrial Areas of India

Apart from the industrial regions described, 13 minor emerging industrial regions are in the country.

- Ambala- Amritsar

- Jaipur- Ajmer

- Indore- Dewas- Ujjain

- Saharampur-Muzaffarnagar- Bijnor

- Kolhapur- South Kannada

- Northern Malabar

- Middle Malabar

- Adilabad – Nizamabad

- Prayag- Varanasi- Mirzapur

- Bhojpur- Munger

- Durga- Raipur

- Bilaspur- Korba

- Brahmaputra valley

Key Industries of the Minor Industrial Areas

Apart from the above Minor Industrial areas, Some other famous Industrial areas in India are listed below.

Kanpur-Lucknow Industrial Region

- Textiles: Kanpur and Lucknow have established themselves as major centres for cotton, woollen, and jute textiles, producing a wide range of fabrics and garments for domestic and international markets.

- Leather Goods: The region boasts a strong leather goods industry, particularly in Kanpur, renowned for its high-quality shoes, bags, and other leather products.

- Fertilizers and Chemicals: Kanpur houses several fertilizer and chemical factories, contributing to agricultural productivity and industrial development.

- Pharmaceuticals: Lucknow is emerging as a prominent pharmaceutical hub, attracting major pharmaceutical companies and contributing to India’s growing pharmaceutical industry.

- Electric Goods and Light Machinery: Kanpur has a well-developed industry that manufactures electric goods and light machinery, catering to various sectors like electronics and engineering.

- Other Industries: The region also houses a significant presence of other industries like food processing, rubber products, and paper mills, contributing to its economic diversification.

Assam Valley Industrial Region

- Petrochemicals: Assam boasts rich natural gas reserves, fueling a thriving petrochemical industry, with centres like Bongaigaon and Digboi producing fertilizers, plastics, and other essential products.

- Jute and Silk Textiles: The region has a long history of textile production, with renowned centres like Guwahati and Tinsukia specializing in jute and silk textiles, contributing significantly to the state’s cultural heritage and economy.

- Tea Processing: Assam’s world-famous tea is processed in numerous factories across the region, with Dibrugarh and Tinsukia being major hubs, contributing to the state’s export earnings and employment opportunities.

- Paper and Plywood: Assam’s abundant forest resources support a thriving paper and plywood industry, with factories producing paper for various uses and plywood for construction and furniture.

- Match Industry: The region is home to a significant match industry, with centres like Noonmati producing matches that are distributed throughout the country.

- Food Processing: With fertile agricultural land, Assam has a robust food processing industry, focusing on processing fruits, vegetables, and grains, contributing to food security and generating employment.

Darjeeling-Siliguri Industrial Region

- Tea Processing: Darjeeling is synonymous with its world-renowned Darjeeling tea, with numerous tea estates and processing facilities employing a significant portion of the workforce.

- Tourism: Darjeeling’s breathtaking beauty, hill stations, and colonial architecture attract tourists from all over the world, fueling a booming tourism industry.

- Food Processing: Siliguri serves as a major hub for food processing, with factories and mills processing regional agricultural products like tea, fruits, vegetables, and grains.

- Trade and Logistics: Situated at the intersection of crucial trade routes, Siliguri thrives as a commercial centre, with warehouses, transportation companies, and wholesale markets.

- Engineering and Manufacturing: Siliguri’s engineering and manufacturing sector rapidly produces diverse products such as light machinery, electronics, and pharmaceuticals.

- IT and BPO: The IT and BPO industry is rising in Siliguri, with numerous companies establishing call centres and other back-office operations.

- Healthcare: Siliguri boasts well-equipped hospitals and medical facilities, catering to the local population and attracting patients from nearby regions.

These industries, along with others like sericulture, floriculture, rubber-based industries, and hydropower, contribute significantly to the economic prosperity and development of the Darjeeling-Siliguri Industrial Areas.

North Bihar and Eastern Uttar Pradesh Industrial Region

Recognized for its significant presence in sugar, cement, glass, jute, fertilizers, locomotive, paper, and food processing industries. Primary industrial centers are Allahabad, Dalmianagar (Bihar), Gorakhpur, Patna, Sultanpur, and Varanasi.

Indore-Ujjain Industrial Region

- Automobiles: Indore is home to several renowned automobile manufacturers like Mahindra & Mahindra, Tata Motors, and Fiat.

- Pharmaceuticals: A major pharmaceutical hub, Indore boasts leading companies like Cipla, Ajanta Pharma, and Lupin.

- Textiles: Indore has a rich textile legacy, with a thriving textile industry producing cotton, synthetic, and blended fabrics.

- Food Processing: With its fertile agricultural belt, the region boasts a robust food processing industry, processing fruits, vegetables, and grains.

- IT/ITeS: Indore is a burgeoning IT hub, attracting companies like Infosys, TCS, and Wipro.

- Electronics and Engineering Goods: The region has a growing electronics and engineering goods sector that manufactures various products.

Amritsar Jalandhar-Ludhiana Industrial Region

- Sports Goods: The region is a global leader in sports goods production, with Ludhiana earning the nickname “India’s Sports City.” Companies like BDM International, Adidas, and Nivia manufacture everything from footballs to cricket bats.

- Textiles: Amritsar and Jalandhar have a long-standing tradition in textile production, specializing in cotton, woolen, and hosiery. From intricate shawls to comfortable clothing, the region caters to diverse domestic and international markets.

- Food Processing: Punjab’s fertile agricultural land fuels a thriving food processing industry within the region. Companies like Verka and ITC process fruits, vegetables, and milk into a variety of food products.

- Hosiery: Ludhiana is a major hosiery hub, producing a wide range of garments, including socks, underwear, and t-shirts. Brands like Amante and Monte Carlo have their roots in the region.

- Tourism: Amritsar, home to the Golden Temple, is a major pilgrimage center attracting tourists worldwide. Jalandhar also boasts historical sites and cultural attractions contributing to the region’s tourism industry.

This amalgamation of traditional and modern industries, coupled with its strategic location and entrepreneurial spirit, makes the Amritsar Jalandhar-Ludhiana Industrial Region a vital contributor to Punjab’s economic strength.

Nagpur-Wardha Industrial Region

- Textiles: The region boasts a strong textile industry, particularly in cotton textiles, with prominent centers like Nagpur and Wardha producing a variety of fabrics and garments.

- Engineering: The region is home to a thriving engineering sector, encompassing a wide range of manufacturing activities, from heavy machinery and equipment to components and electronics.

- Chemicals: The Nagpur-Wardha region has a well-established chemical industry that produces various chemicals and fertilizers and contributes to India’s agricultural and industrial sectors.

- Food Processing: With fertile farmlands surrounding the region, the food processing industry plays a crucial role, in processing fruits, vegetables, and grains into diverse food products.

- Iron and Steel: Nagpur is a significant center for iron and steel production, with major plants like Sesa Sterlite and SAIL contributing to India’s steel production capacity.

- Shipbuilding: The region has a long history of shipbuilding, with centers like Vishakhapatnam boasting major shipyards contributing to India’s maritime industry.

- Fertilizer: Wardha houses a major fertilizer production facility operated by Rashtriya Chemicals & Fertilizers Ltd., supplying essential agricultural inputs across the country.

- Rice Milling: The region is a major rice-producing area, with numerous rice mills processing the grain for local and national consumption.

- Sugar: Nagpur is known for its sugar mills, contributing to India’s sugar production and export.

- Fish Processing: Vishakhapatnam is a significant center for fish processing, exporting fish and seafood products globally.

- Other Industries: The region also houses diverse industries, including engineering, chemicals, pharmaceuticals, and food processing, contributing to its economic diversification.

This rich blend of industries, along with a skilled workforce and favorable infrastructure, positions the Nagpur-Wardha Industrial Region as a major contributor to Maharashtra’s and India’s economic development.

Dharwar-Belgaum Industrial Region

- Cotton Textiles: The region has a long-standing tradition in cotton textiles, with Belgaum being renowned for its powerloom industry and Dharwad known for its textile engineering and machinery manufacturing.

- Chemicals: Dharwad houses a significant chemical industry, particularly in pharmaceuticals and plastics, contributing to the region’s diverse industrial base.

- Spice Packing: Belgaum is a major center for spices packing, processing, and export, leveraging its proximity to spice-producing areas.

- Food Processing: The fertile lands surrounding the region support a thriving food processing industry, focusing on fruits, vegetables, and grains.

- Electronics and IT: A nascent IT sector is emerging in Belgaum, attracting companies and creating job opportunities.

- Auto Components: Dharwad is seeing the development of an auto components manufacturing sector that caters to the growing automotive industry in India.

- Renewable Energy: Both Dharwad and Belgaum are exploring the potential of renewable energy, with initiatives in solar and wind power generation.

This combination of established industries and promising new ventures positions the Dharwar-Belgaum Industrial Region for continued growth and diversification, contributing significantly to Karnataka’s economic development.

Kerala Coast Industrial Region

- Coconut Oil Extraction: Kerala’s reputation as the “Land of Coconut” translates into a thriving coconut oil extraction industry, with numerous mills processing coconuts into oil for domestic and export markets.

- Rice Milling: The fertile plains bordering the coast provide fertile ground for rice cultivation, supporting a robust rice milling industry that processes rice for local consumption and distribution.

- Fish Packing: With its rich fishing resources, the region is a major center for fish packing, processing, and export, contributing significantly to the state’s economy and providing employment for coastal communities.

- Paper: The coastal region houses several paper mills, utilizing local resources like bamboo and wood pulp to produce a variety of paper products.

- Coir Matting: Kerala is renowned for its coir products, and the coastal region plays a crucial role in coir matting production, utilizing coconut husks to create durable and eco-friendly floor coverings.

- Shipbuilding (Kochi): The port city of Kochi boasts a long history of shipbuilding, with major shipyards like Cochin Shipyard Ltd. contributing to India’s maritime industry.

- Petroleum Refining (Kochi): Kochi houses a major oil refinery, the BPCL Kochi Refinery, supplying petroleum products to meet the state’s and the country’s energy needs.

- Chemical and Electronic Goods Production: The region is witnessing a growing presence of industries like chemicals and electronics, diversifying its industrial landscape and attracting investment.

This blend of traditional industries like coconut oil extraction and coir matting, alongside modern sectors like shipbuilding and petroleum refining, positions the Kerala Coast Industrial Region as a crucial contributor to the state’s economic growth and development.

Conclusion

Industrial areas emerge as a result of favorable geo-economic conditions, becoming hubs where businesses concentrate their operations. These areas witness significant industrial production and employment.

The development of industrial areas occurs when a critical mass of business owners converges, acknowledging the benefits of proximity. They choose to cluster in specific locations due to advantageous locational factors.

The classification of industries within these areas relies on various indicators, such as the concentration of similar businesses, the number of industrial workers, and the advantages offered by the producers.

More Topics on Geography: